Featured Project Return to Projects List

PS1 Moma Museum

Project Information

- Project Location:

- Long Island, NY

- Status:

- Completed - Oct 2023

- Structure Type:

- Museum

Scope Of Work

The scope of your project at the MoMA museum included the following key aspects:

Assessment and Planning: Inspection: Detailed inspection of the existing corroded chimney to assess the extent of corrosion and potential structural issues.

Measurements: Precise measurements to ensure the new chimney fits properly within the existing space constraints.

Regulatory Compliance: Ensuring the new chimney meets all local building codes and regulations.

Design and Specification: Material Selection: Choosing the appropriate grade of stainless steel, typically 304 or 316, for the double-wall chimney.

Design Specifications: Designing the double-wall system, including insulation material and required thickness.

Logistical Challenges and Planning: Access Constraints: Developing a plan to address limited access to floors where the chimney penetrates.

Safety Measures: Implementing safety measures to protect workers, museum staff, and exhibits.

Dust Control: Arranging effective dust control measures to prevent contamination and maintain air quality.

Removal of the Existing Chimney: Safety Precautions: Ensuring worker safety and protecting museum property during the removal process.

Dismantling: Carefully dismantling the corroded chimney, using cranes or other equipment as needed.

Disposal: Proper disposal of the corroded steel, adhering to environmental regulations.

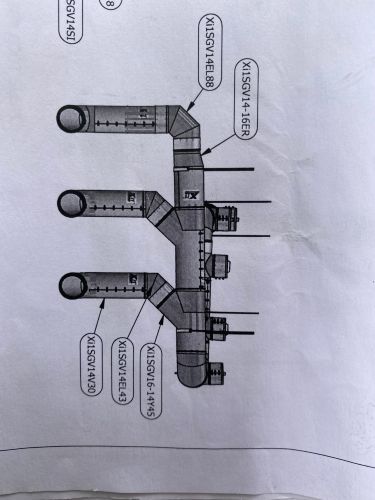

Installation of the New Chimney: Foundation Preparation: Ensuring the base or foundation is suitable for the new chimney.

Assembly: Assembling the double-wall stainless steel chimney sections according to specifications.

Insulation Installation: Installing the insulation between the inner and outer walls.

Securing the Chimney: Properly anchoring the chimney to the structure.

Operational Constraints: Scheduling: Working on days when the museum was closed to the public to minimize disruption.

Noise and Vibration Control: Implementing measures to control noise and vibrations to prevent disturbance to the museum environment.

Connection and Testing: System Integration: Connecting the new chimney to existing heating or exhaust systems.

Testing: Conducting tests to ensure no leaks and proper draft and pressure.

Safety Checks: Performing final safety checks.

Final Inspection and Documentation: Inspection: Final inspection by a certified professional.

Documentation: Detailed documentation of the installation, materials used, tests performed, and compliance certifications.

Maintenance Plan: Maintenance Schedule: Establishing a regular maintenance schedule.

Inspection Guidelines: Periodic inspections to check for any signs of wear or issues.

By addressing these steps and overcoming the specific challenges posed by the museum environment, your team successfully replaced the chimney while ensuring safety and compliance.