Featured Project Return to Projects List

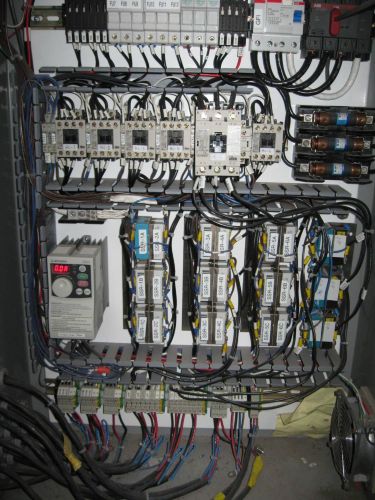

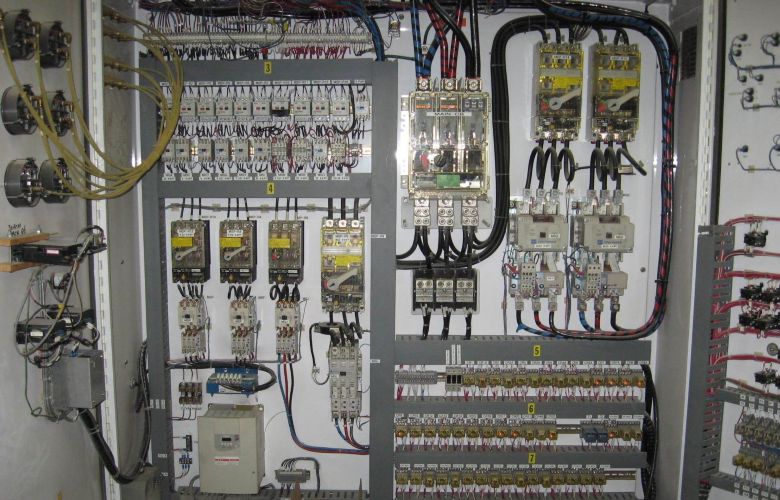

480V Electrical Control Panel

Project Information

- Project Location:

- x, NJ

- Status:

- Completed

- Structure Type:

- Manufacturing Plant

References

- Owner:

- Food Processing Plant

Scope Of Work

Industry: Food

Application: 480V Electrical Control Panel

Savings: Overall savings to client……..over $600,000

Downtime on the packaging line was reduced from 42-48 days to 4 days. Cost of labor and materials was less than 30% of OEM pricing.

Issue: Fire damaged European made electrical control box

Problem: The panel was built in Europe. The client would have waited 6-8 weeks to get a replacement from overseas. This particular control

panel controlled one of 4 chopped lettuce packaging lines, meaning that 25% of production was down. Our hero customer was facing the possible loss of major customer accounts if he couldn’t deliver product on time.

Alternatives: Wait 6-8 weeks for delivery from Europe. Pay higher OEM prices.

Solution: Marshall Industrial Technologies Electrical Service Group responded to the emergency immediately and transported the damaged control panel to our shop where our technicians provided new back panel, relays and connections and re-energized the packaging system in 4 days.

Heartwarming Success: Our hero customer was able to maintain deliveries to all of his key customer accounts thereby preventing monumental revenue losses and serious damage to his reputation.

Other Applications: Marshall’s skilled Electrical Service technicians can build or re-build electrical control and distribution systems both in house and on site.

Industry: Food

Application: 480V Electrical Control Panel

Savings: Overall savings to client……..over $600,000

Downtime on the packaging line was reduced from 42-48 days to

4 days. Cost of labor and materials was less than 30% of OEM pricing.

Issue: Fire damaged European made electrical control box

Problem: The panel was built in Europe. The client would have waited 6-8

weeks to get a replacement from overseas. This particular control

panel controlled one of 4 chopped lettuce packaging lines, meaning

that 25% of production was down. Our hero customer was facing the possible loss of major customer accounts if he couldn’t deliver product on time.

Alternatives: Wait 6-8 weeks for delivery from Europe. Pay higher OEM prices.

Solution: Marshall Industrial Technologies Electrical Service Group

responded to the emergency immediately and transported the damaged

control panel to our shop where our technicians provided new back panel,

relays and connections and re-energized the packaging system in 4 days.

Heartwarming Success: Our hero customer was able to maintain deliveries to all of his key customer accounts thereby preventing monumental revenue losses and serious damage to his reputation.

Other Applications: Marshall’s skilled Electrical Service technicians can build or re-build electrical control and distribution systems both in house and on site.